PMS5003 PM2.5 Air Particle Dust laser Sensor Digital Module

Categories :

Gas / PM2.5/ AlcoholSKU :

180861Overview

The PMS5003 is a digital universal particle concentration sensor based on the principle of laser scattering. It can continuously collect and calculate the number of suspended particulates in different air volumes per unit volume, that is, the particle concentration distribution, and then convert it into mass concentration. Interface form output. The sensor can be embedded in a variety of suspended particles in the air associated with the concentration of instrumentation or environmental improvement equipment, to provide timely and accurate concentration data.

Working principle

The sensor uses the principle of laser scattering. It means that the laser light on the particles in the air and making the scattering, while collecting scattered light at a particular angle , resulting in scattered light intensity with time curve. Furthermore, the microprocessor uses the algorithm based on Mie (MIE) to obtain the equivalent particle size of the particles and the number of particles with different particle diameters per unit volume.

Features

- The principle of laser scattering to achieve accurate measurement

- Zero error alarm rate

- Real-time response and support for continuous acquisition

- Minimal resolution particle size 0.3um

- The new patent structure, six full range of shielding, anti-jamming performance stronger

- Inlet direction is optional, the use of a wide range of users without the need for duct design

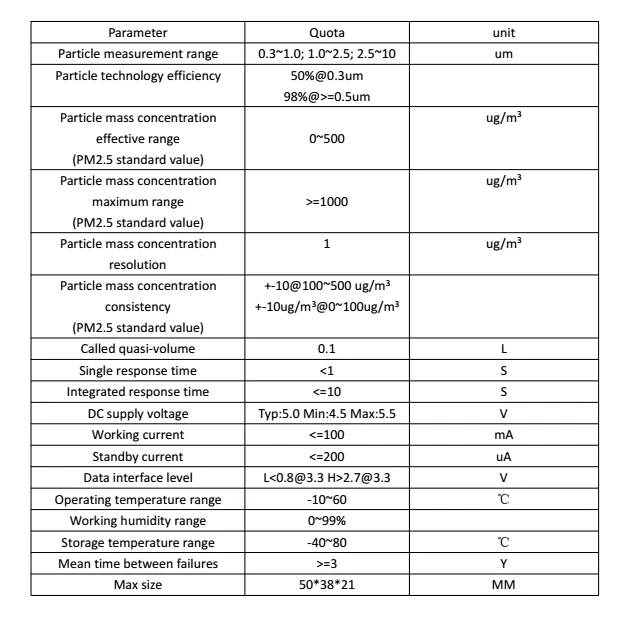

Technical indicators

Note:

1) The maximum range refers to the sensor to ensure that the PM2.5 standard value of the maximum output value of not less than 1000 micrograms / cubic meter. 1000 micrograms / l cubic meters above the measured subject.

2) Particle concentration consistency data for the communication protocol in the data 2 (see Appendix A) to measure the environmental conditions of 20 degrees Celsius, humidity of 50%.

Output the result

The main output is the mass per unit volume of particles and the number of particles, of which the number of particles per unit volume of 0.1 liters, the mass concentration in units of micrograms / cubic meter

The output is divided into active output and passive output. After the power is turned on, the default state is active output: the sensor will take the host to send the running data, the time interval is 200 ~ 800ms, the higher the concentration of particles in the air, the shorter the time interval. Active output is divided into two modes: smooth mode and fast mode. When the change in particle concentration in the air is small, the sensor output is a smooth mode: the same set of values is output every three times, and the actual data is about 2s with the new period. When the concentration of particles in the air changes greatly, the sensor output automatically switches to fast mode, each output is a new value, the actual data update cycle of 200 ~ 800ms.

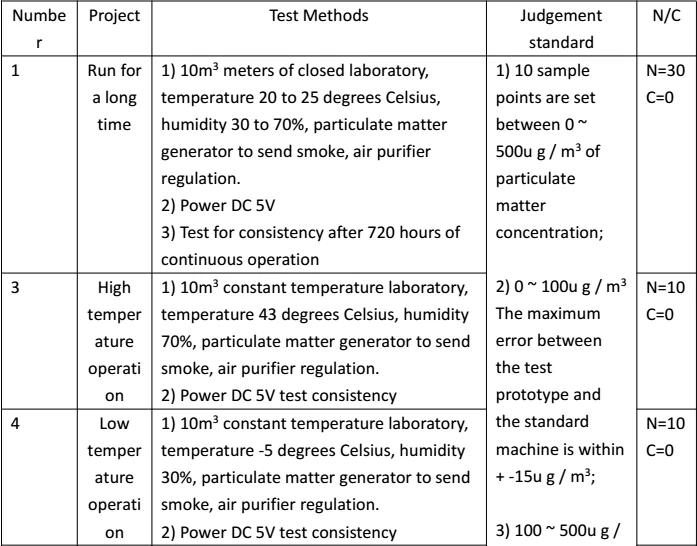

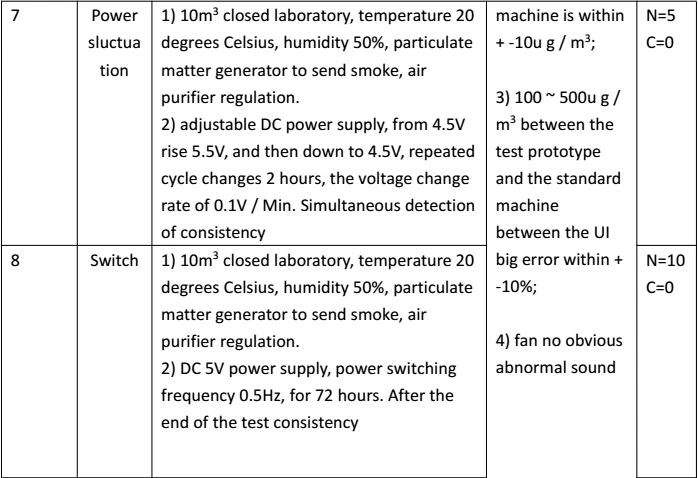

Reliability test

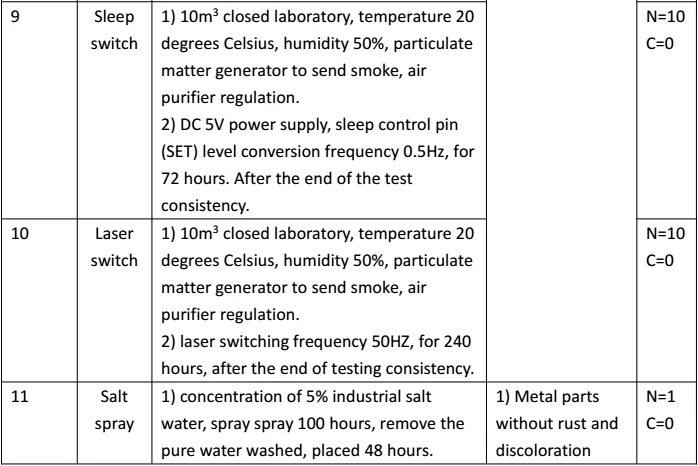

Size(mm)

Installation Precautions

1) The metal case is connected to the internal power source. Be careful not to connect with other external board groups or chassis.

2) the air inlet and outlet where the plane close to the user's machine wall and the outside of the pores connected to the best installation, such as can not be achieved, the outlet around 2cm without shelter. Between the air inlet and the outlet should be the structure of the air separation, to avoid air flow inside the user from the outlet directly back to the air inlet.

3) The inner wall of the user's machine shall not be smaller than the size of the air inlet.

4) When applying to the purifier, try to avoid placing the sensor directly in the purifier's own air duct. If it is unavoidable, set up a separate structural space and place the sensor in the same way as the purifier's own duct isolation.

5) Application with the purifier or fixed detection equipment, the sensor position should be higher than the ground 20cm or more. Otherwise there may be near the ground of large dust particles and even floc contamination caused by fan winding resistance.

6) sensors used in outdoor fixed equipment, for dust storms, rain and snow and the protection of Yang catkins, should be completed by the equipment.

7) The sensor is an integral part and the user will not disassemble it, including metal shields, to prevent irreversible damage.

8) The bottom of the sensor is fixed with 2mm tapping screw, the screw into the shell length should not be greater than 5mm.