PMS5003ST PM2.5 Formaldehyde Temperature and Humidity laser Sensor Digital Module

Categories :

Gas / PM2.5/ AlcoholSKU :

180868Overview

PMS5003ST series is a can monitor the concentration of air in the air, formaldehyde concentration and temperature and humidity of the three in one sensor. The monitoring of particulate matter concentration based on the principle of laser scattering, continuous collection and calculation of the unit volume of air in different particle size of the number of suspended particles, that is, particle concentration distribution, and then converted into a mass concentration. Formaldehyde concentration monitoring based on electrochemical principles, with a high degree of precision, high stability characteristics. The sensor is also equipped with Swiss temperature and humidity detection chip. Particle concentration values, formaldehyde concentration values and temperature, humidity combined to the general form of digital interface output. The sensor can be embedded in a variety of air quality monitoring and improvement related equipment, to provide timely and accurate environmental parameters.

Working principle

The sensor uses the principle of laser scattering. It means that the laser light on the particles in the air and making the scattering, while collecting scattered light at a particular angle , resulting in scattered light intensity with time curve. Furthermore, the microprocessor uses the algorithm based on Mie (MIE) to obtain the equivalent particle size of the particles and the number of particles with different particle diameters per unit volume.

Characteristic

- The principle of laser scattering to achieve accurate measurement

- Zero error alarm rate

- Real-time response and support for continuous acquisition

- Minimal resolution particle size 0.3um

- The new patent structure, six full range of shielding, anti-jamming performance stronger

- Inlet and outlet direction optional, wide range of applications, users do not need to design in the duct

- Real-time output of formaldehyde monitoring data

- Real-time output temperature and humidity data

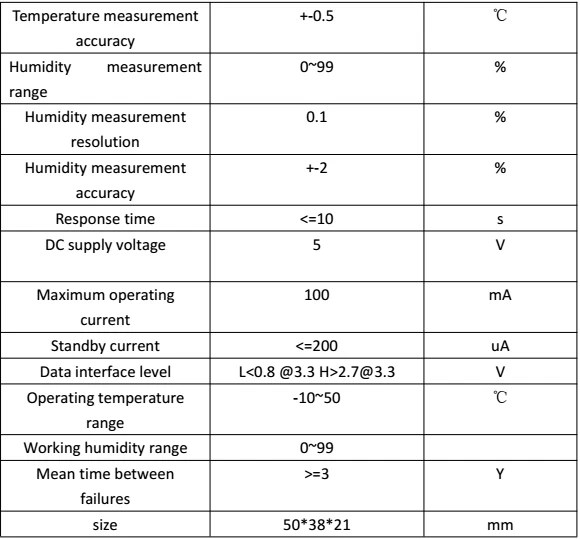

Technical indicators

Output the result

1. Particle concentration: Active output is the mass per unit volume of particles and the number of particles, of which the number of particles per unit volume of 0.1 liters, the mass concentration unit: micrograms / cubic meter. In addition the sensor output is divided into active output and passive output of two states. When the sensor is powered on, the default state is active output, that is, the sensor sends the serial data to the host, the time interval is 200 ~ 800ms, the higher the concentration of particles in the air, the shorter the time interval. Active output is divided into two modes: smooth mode and fast mode. When the change in particle concentration in the air is small, the sensor output is a smooth mode, that is, the same set of values is output every three times, and the actual data update period is about 2s. When the concentration of particles in the air changes greatly, the sensor output automatically switches to fast mode, each output is a new value, the actual data update cycle of 200 ~ 800ms. PWM output: PMS3XXXP series with PWM output, PWM cycle of 1 second, low time length represents PM2.5 concentration (atmospheric environment), per 1ms low level represents 1ug / m. For example, low time length 210ms, it represents the PM2.5 mass concentration (atmospheric environment) is 210ug / m

2. Formaldehyde concentration output: the concentration of formaldehyde per unit volume, in milligrams / cubic meter

3. Temperature and humidity output: output suction sensor inside the sampling air temperature tens of degrees.

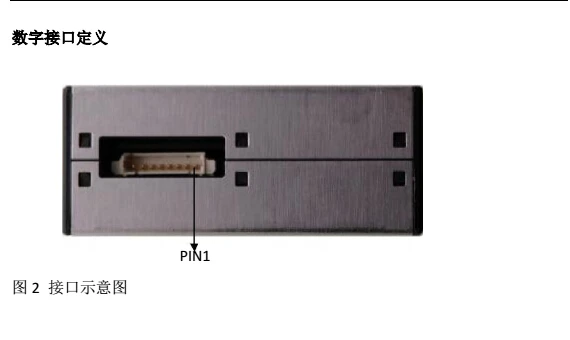

Circuit design should be noted

1) PMS5003ST requires 5V power supply, this is because the fan needs 5V drive. But other data communication and control pins require 3.3V as a high level. So the motherboard MCU with which to connect the communication should be 3.3V power supply. If the motherboard MCU is supplying 5V, the level conversion chip or circuit should be added to the communication line (RXD / TXD) and the control line (SET / RESET).

2) SET and RESET have a pull-up resistor inside, if not applicable, should be left floating.

3) Pin7 and Pin8 for the program back debugging, the application circuit should be vacated.

4) When applying the sleep function, it should be noted that the fan stops working at sleep and the fan restart requires a stabilization time of at least 30 seconds. Therefore, for accurate data, the sensor should not be operated for less than 30 seconds after wake-up.

Installation Precautions

1) The metal case is connected to the internal power source. Be careful not to connect with other external board groups or chassis.

2) The air inlet and outlet where the plane close to the user's machine wall and the outside of the pores connected to the best installation, such as can not be achieved, the outlet around 2cm without shelter. Between the air inlet and the outlet should be the structure of the air separation, to avoid air flow inside the user from the outlet directly back to the air inlet.

3) The inner wall of the user's machine shall not be smaller than the size of the air inlet.

4) When applying to the purifier, try to avoid placing the sensor directly in the purifier's own air duct. If it is unavoidable, set up a separate structural space and place the sensor in the same way as the purifier's own duct isolation.

5) Application with the purifier or fixed detection equipment, the sensor position should be higher than the ground 20cm or more. Otherwise there may be near the ground of large dust particles and even floc contamination caused by fan winding resistance.

6) Sensors used in outdoor fixed equipment, for dust storms, rain and snow and the protection of Yang catkins, should be completed by the equipment.

7) The sensor is an integral part and the user will not disassemble it, including metal shields, to prevent irreversible damage.

8) The bottom of the sensor is fixed with 2mm tapping screw, the screw into the shell length should not be greater than 5mm.

9) In order to make the formaldehyde probe fully polarized, the sensor should continue to power for less than 48 hours.

10) In addition to formaldehyde, the other a variety of active gases will affect the electrochemical formaldehyde probe, mainly formaldehyde, acetaldehyde, toluene, xylene, carbon monoxide, hydrogen sulfide and so on.

11) Long-term high concentrations of aldehydes, alcohols and other high concentrations of sensitive gas storage or use, will affect the functional life of the sensor formaldehyde. Especially for a long time beyond the maximum range of saturated gas concentration, will make the sensor formaldehyde function short-term failure, or a certain probability of long-term failure.

12) Corrosive gas environment will also make the function of formaldehyde functional unit to reduce or failure.